The automotive industry is undergoing a rapid transformation, fueled by trends like electric vehicle (EV) adoption, autonomous driving, and smart manufacturing. This evolution demands increased precision, speed, and energy efficiency in production processes. Central to this shift are motor technologies. Two prominent contenders, gear motors and servo motors, each offer unique advantages and disadvantages. Choosing the right motor is crucial for optimizing production line performance. This article delves into the key differences between gear motors and servo motors, exploring their applications within automotive parts production, and highlighting how incorporating advanced motor solutions from companies like MES-Drive can significantly boost speed and energy efficiency.

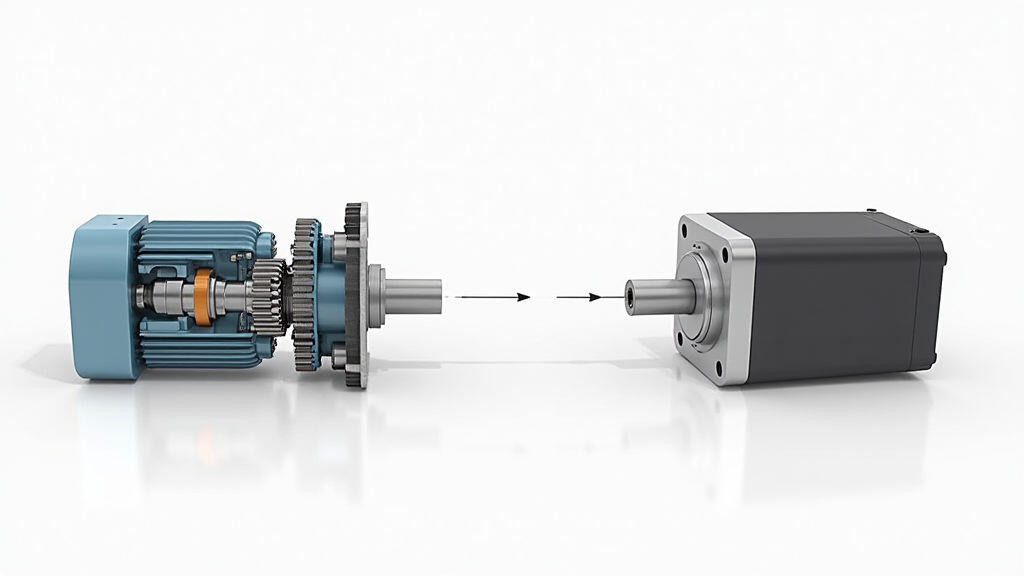

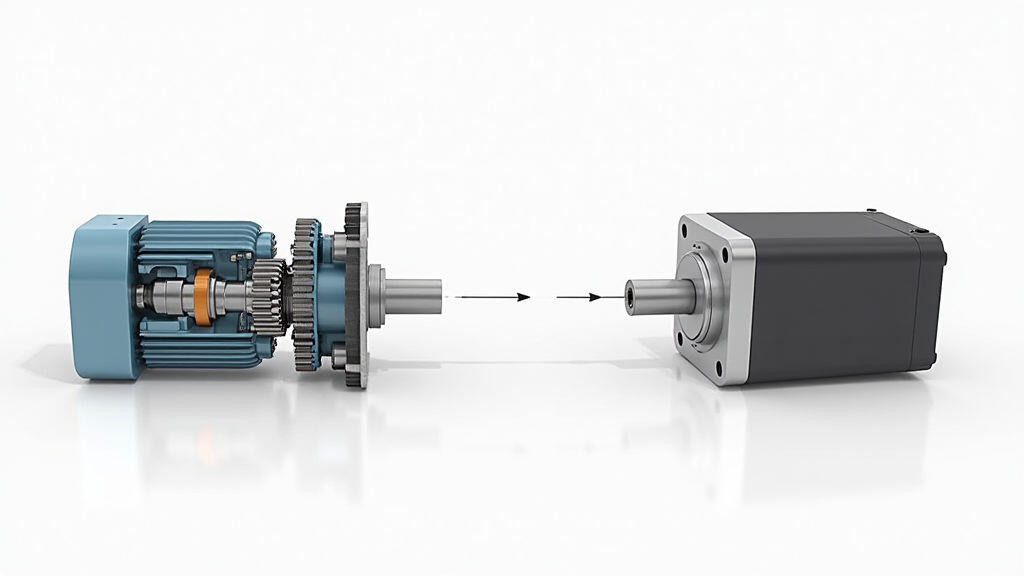

At their core, both gear motors and servo motors are electric motors designed to provide rotational motion. However, their operating principles and capabilities differ significantly:

Gear Motors: These motors incorporate a gearbox to reduce speed and increase torque. This is achieved by using a series of gears to amplify the force generated by the motor. Gear motors are generally simpler in design and more cost-effective than servo motors. They are excellent for applications requiring high torque at lower speeds, such as powering conveyors, pumps, and other auxiliary equipment. They provide a fixed speed output depending on the motor and gearbox combination.

Servo Motors: Servo motors, on the other hand, are closed-loop systems. This means they utilize feedback mechanisms (e.g., encoders) to continuously monitor and adjust their position, velocity, and torque. A sophisticated control system compares the desired position with the actual position and corrects any discrepancies, ensuring precise and accurate operation. Servo motors offer superior responsiveness, control, and accuracy, making them ideal for applications requiring complex motion control.

Here's a breakdown of the crucial differences between the two motor types:

| Feature | Gear Motor | Servo Motor | |----------------------|---------------------------------------------|----------------------------------------------| | Speed | Fixed, depends on motor & gearbox ratio | Variable, precisely controllable | | Torque | High at lower speeds | Variable, high torque at various speeds | | Accuracy | Lower | Significantly higher, closed-loop control | | Complexity | Simpler | More complex, requires feedback system | | Cost | Generally lower | Generally higher | | Efficiency | Can be lower due to gearbox losses | Generally higher, more efficient operation | | Control | Basic control, typically on/off or speed adjustment | Precise position, velocity, and torque control | | Maintenance | Typically lower | Can be higher due to complex components |

The automotive parts manufacturing industry presents diverse requirements, ranging from heavy-duty tasks like stamping and forging to delicate operations like precision machining and assembly. Here’s how both gear motors and servo motors are utilized:

Gear Motors:

Servo Motors:

MES-Drive specializes in providing high-performance motor solutions tailored for the automotive industry. Their range includes both gear motors and servo motors, designed to meet the specific needs of various production processes.

MES-Drive's servo motors, equipped with advanced encoders and sophisticated control algorithms, offer:

The trend toward sustainability and smart manufacturing are driving increased demand for energy-efficient and digitally integrated motor solutions. Regulations regarding energy consumption are becoming stricter, compelling automotive manufacturers to adopt more efficient technologies. Furthermore, the integration of IoT (Internet of Things) and IIoT (Industrial Internet of Things) technologies is enabling real-time monitoring and optimization of motor performance, leading to further energy savings and improved productivity.

MES-Drive is at the forefront of this trend, developing motor solutions that are not only highly efficient but also equipped with digital capabilities for remote monitoring, diagnostics, and predictive maintenance. This proactive approach minimizes downtime and maximizes the lifespan of motor systems.

Choosing the appropriate motor – gear motor or servo motor – is a critical decision for automotive parts manufacturers looking to enhance speed, precision, and energy efficiency. While gear motors excel in applications requiring high torque at lower speeds, servo motors provide unparalleled control and accuracy for complex motion tasks. Companies like MES-Drive are leading the way in providing advanced motor solutions that address the evolving needs of the industry, empowering manufacturers to achieve greater productivity, reduce operational costs, and embrace the principles of sustainable manufacturing. As EVs gain market share and manufacturing processes become increasingly automated, the demand for sophisticated motor technologies like those offered by MES-Drive will continue to surge, solidifying their importance in shaping the future of the automotive parts production landscape. The ongoing push for energy efficiency and digital integration ensures a promising future for these advancements in motor technology.

Leave A Reply

Your email address will not be published. Required fiels are marked